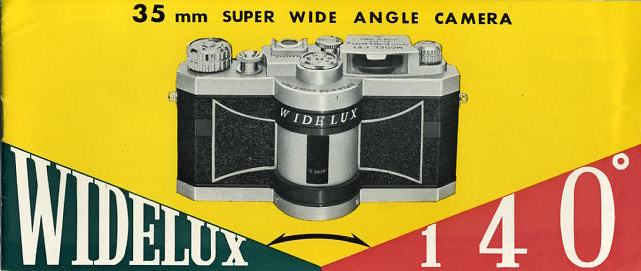

Our exclusive WIDELUX (35mm) restoration service enables us to share a passion with photographers, filmmakers, architects, collectors, and artists from around the world…

–

Keywords : Widelux troubleshooting

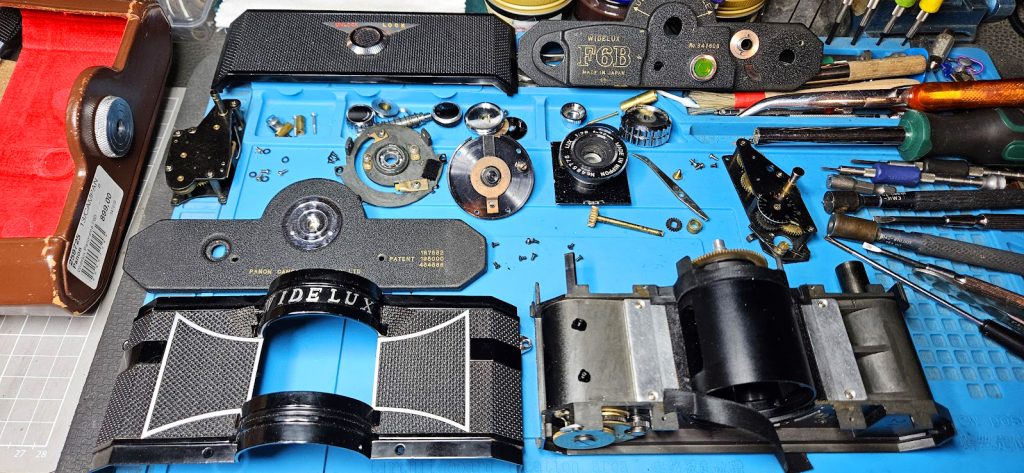

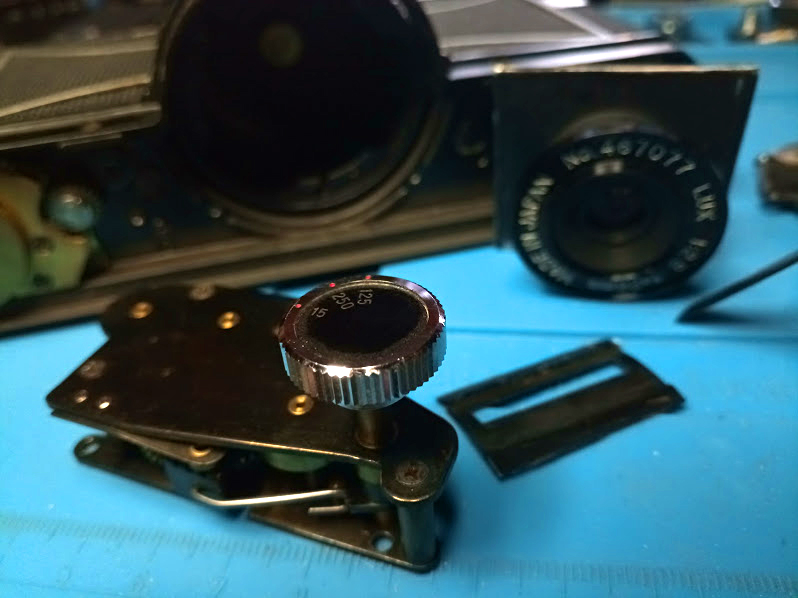

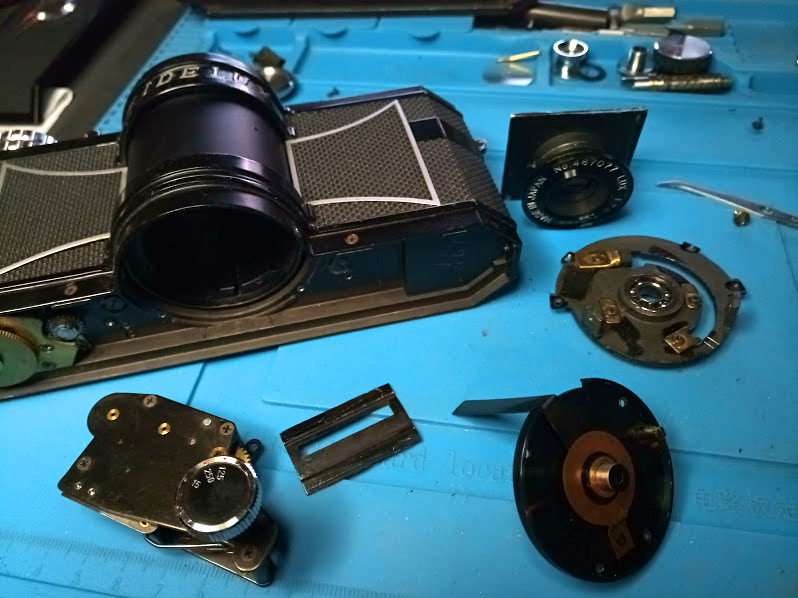

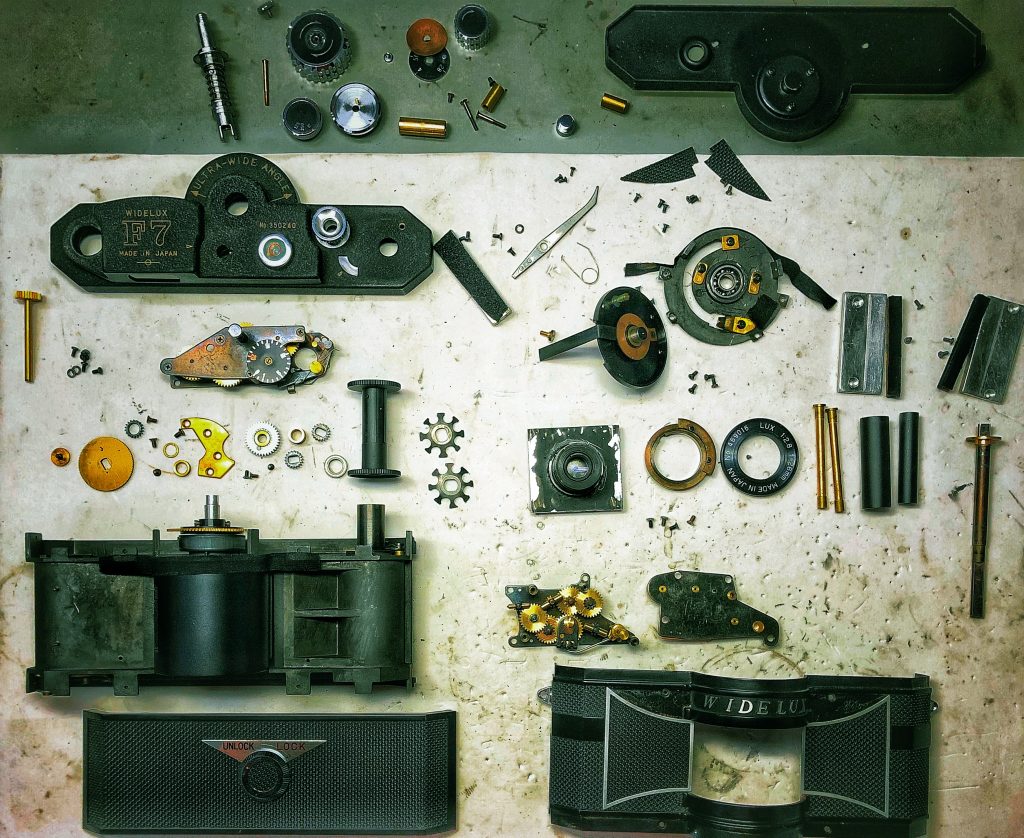

This comprehensive restoration service for WIDELUX is a meticulous procedure that ensures the complete renovation of your camera. We adopt a thorough and meticulous approach to ensure that every component of your camera is restored to its original technical state (while preserving its patina), thus providing optimal performance and long-term reliability. This work requires the absolutely complete disassembly of all parts, their cleaning, lubrication according to the original recommendations, rigorous reassembly, and a series of meticulous calibrations.

Revamping only one function (such as the shutter or film advance function) often makes little sense, as all functions of these panoramic cameras are interdependent, and due to their age, only a complete restoration will guarantee perfect functionality.

This exclusive service is covered by a new one-year warranty. See Art. 10 of our Terms and Conditions of Sale: mondepanneur.fr/cgv.

–

Step 1: Comprehensive inspection

Each WIDELUX is meticulously inspected to identify areas requiring special attention. The camera is completely disassembled, piece by piece, to assess and detect wear, damages, or potential defects. This step is essential to determine if your WIDELUX can be restored. It is important to evaluate its overall condition to ensure that the expense is reasonable and leads to a truly perfect result. It is not feasible to undertake a complete restoration if the wear is too pronounced, as the parts are costly. The desired final reliability is only achievable with WIDELUX cameras in good overall condition that have not suffered significant degradation. This is the key to success!

Step 2: Restoration to factory condition

All parts are restored to factory condition, ensuring optimal operation. We use lubricants recommended for that era, along with specific tools and high-quality materials and surface treatments to restore each component, preserving the authenticity of your WIDELUX.

If necessary, some parts are replaced or custom-made.

Step 3: Thorough functionality testing

Every function of the camera is rigorously tested to ensure proper operation. From the slit shutter to the turret rotation function or the regular film advance… We make sure that all features of your WIDELUX adhere to the original specifications.

Step 4: Cleaning, lubrication, and adjustment (CLA)

We perform a thorough cleaning to remove any dirt, dust, or mold. After fungicidal treatment, we lubricate mechanical parts to ensure smooth and regular movement. Each element is precisely readjusted to ensure optimal performance and minimize wear and tear.

Step 5: Full operating guarantee

All components of a camera depend on one another. That’s why our comprehensive approach ensures the perfect functioning of the entire device. Through our complete restoration, your WIDELUX will not only regain a beautiful appearance but also its original performance.

Choose our exclusive WIDELUX restoration service and bring your vintage camera back to life. Trust our expertise and commitment to excellence to preserve this precious piece of photographic history.

Philippe RAYBAUDI

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

These fully mechanical panoramic cameras are works of art! They are microengineering gems invented by ingenious technicians.

The restoration and regular maintenance (CLA) of WIDELUX cameras require the expertise of a specialized workshop, as well as specific high-quality tools and lubricants.

If you want your WIDELUX to bring you joy and delight future generations, consider a complete restoration, and have it serviced every 5 years.

Before shipping your WIDELUX to me, please fill out the following form: https://mondepanneur.fr/mes-services/estimer-une-reparation

–

So that the passion lives!

Widelux history: https://fr.qwe.wiki/wiki/Widelux

Keywords : Widelux troubleshooting

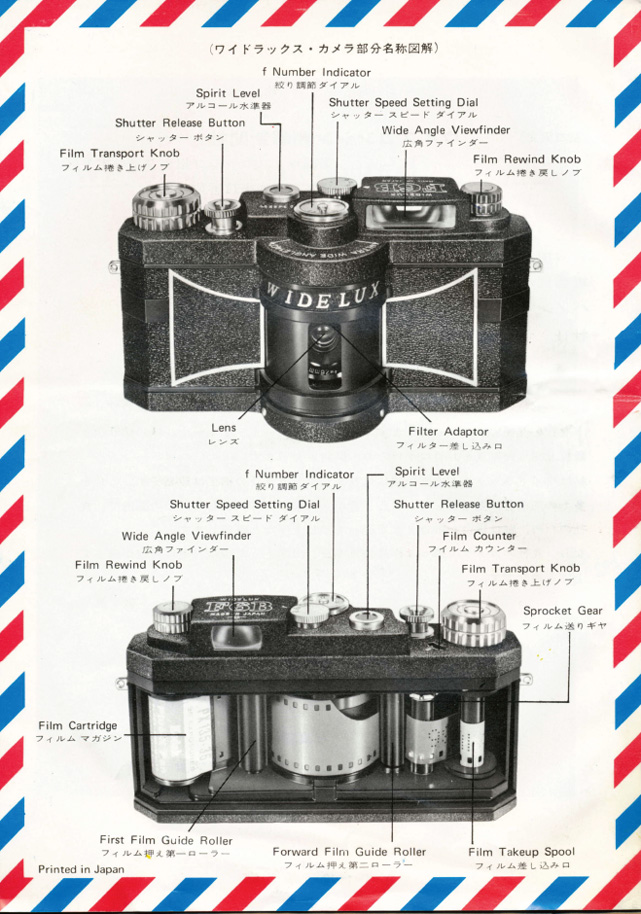

Some of the restoration operations for a WIDELUX include:

- Complete disassembly of all parts, cleaning, and fungicidal treatment,

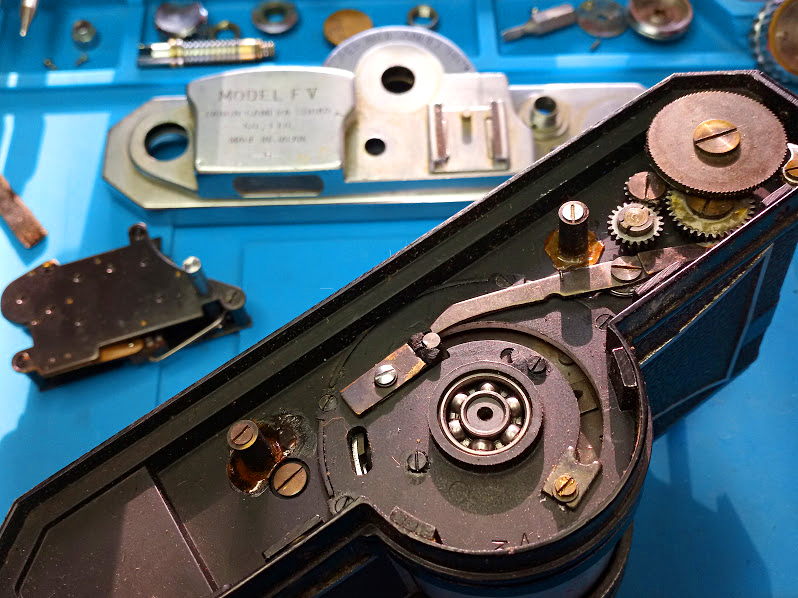

- Disassembly of the shutter speed mechanisms and the control of the rotating turret,

- Disassembly of the anti-reverse clutch for the slowest speed,

- Check that all six flyweights move freely in the three centrifugal governors,

- Surface treatment of oxidized parts (electrolysis, bluing, painting…),

- Resurfacing the gear shaft bearings on the speed selector plates using a watchmaker’s staking tool, with the possible addition of bushings,

- Degreasing and lubrication of slow-rotating shaft bearings with Molykote 44,

- Degreasing and lubrication of fast bearings with Moebius 9010,

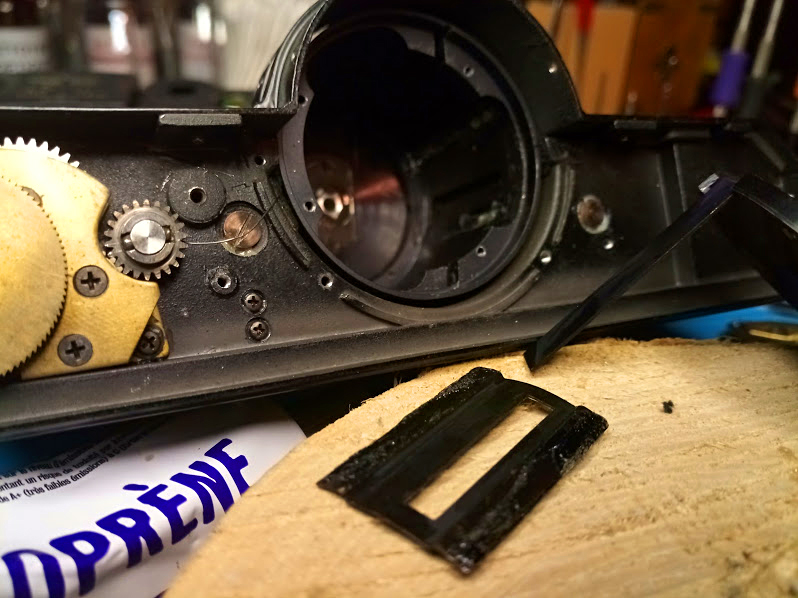

- Disassembly of the slit shutter mechanism,

- Disassembly of the turret and lens mounting plate,

- Cleaning of the well, cogwheel, and its axis with benzene,

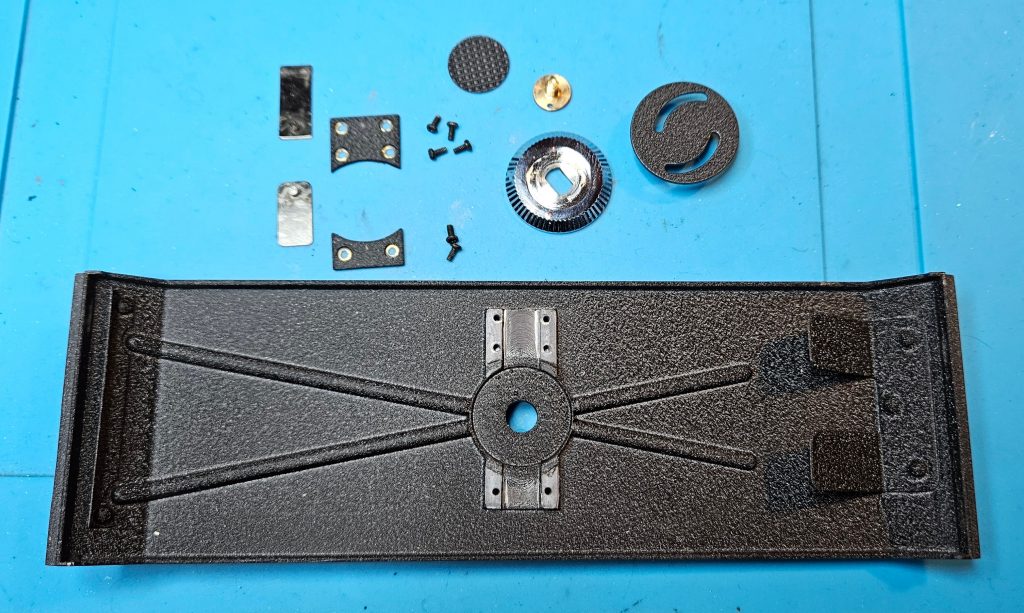

- Fabrication of new parts: end-of-travel damper for the turret with its light seals and felt, back seals, etc.,

- Reassembly and lubrication of the bottom cogwheel with MOS2 grease (molybdenum disulfide) or hyper-grease GR2,

- Adjustments of the gear tensions,

- Checking the tension of the detent ball spring (blade) for the gear shift.

- Synchronization of the turret with the winding mechanism and the leaf shutter,

- Disassembly, cleaning, and greasing of the toothed diaphragm control ring,

- Cleaning of the lens barrel and lubrication of the aperture ring,

- Unscrewing the front lens to clean optical blocks and clean the diaphragm,

- Preventive fungicidal treatment of lenses and parts of the lens in a UV chamber,

- Modification of the button retention on the speed selector shaft,

- Checking gear rotation at all speeds and the slow-speed anti-reverse mechanism.

- Verification of speeds and controls,

- Complete reassembly with calibrations,

- Conducting a test film.

–